So, what's in a box? Seemingly nothing. But it's the promise of a box that I find so compelling. Imagine what can go into that box -- photos, letters, notes passed, trinkets, and, best of all, memories. It is the idea of pulling all those wildly scattered items together that I find so appealing.

I make boxes out of book board, which is a fantastic material. It also goes by the name "Davey board." To call it "cardboard" is to do it a great disservice. It is the same material that you will find on the outside of a hardback book. It comes in three common thicknesses -- sort of flimsy, just right, and really tough to cut. I prefer the "just right" thickness for the boxes that I build. It measures in at about 1/8 of an inch in thickness.

|

| Midweight bookboard, ready for cutting |

So I took the plunge after reading a bookbinder's blog and purchased a fantastic time-saving, finger-saving, and highly accurate Kutrimmer 1071. It is shown below in all it's glory.

|

| Kutrimmer 1071, heavy duty table top trimmer |

What used to take me hours of patient cutting now takes a mere 5 minutes and the accuracy and cleanness of the cuts are superb.

So now that I possess the ability to cut book board rapidly and accurately, the next dilemma to solve is: what kind of box? There are a few "standard" types -- clamshell (also known as a drop spine box), hinged lid, and removable lid. There are, of course, a myriad of variations within each of these standard box types. And I don't mean for my list to be exhaustive. Since I have been making a number of hinged lid boxes lately, I will focus on this type for the rest of this post.

A hinged box consists of a base box surrounded by a "slipcase." A photo of the finished product is shown below.

|

| Completed hinged box |

Construction of this type of box begins with cutting the pieces for the box as well as for the slipcover.

|

| Cut book board pieces for a hinged box |

The pieces for the base box are labeled A, B, and C, while the slipcase pieces are D (two pieces) and E. The slipcase is designed to be a little bit larger than the box so that the lid overhangs the box, as can be seen from the completed photo above.

The box construction proceeds using a glue specifically made for bookbinding (and box making), PVA, polyvinyl acetate.This is a wonderful product! If you are interested in any type of papercraft, be sure to use a pH neutral PVA (one specifically made for bookbinding). This glue is neither too thick nor too thin and it dries neither too fast nor too slow. In other words, it's ideal for applying to book board or paper and being able to move things around a bit before it dries.

Glue is applied to the edges of all the pieces for the base box and held in place, checking that the edges are square. When all pieces are in place, I usually bind the box with rubber bands and let things dry at least overnight.

|

| Two base boxes secured with rubber bands while the glue dries |

While waiting for the base box to dry, it's time to select paper and the material for the hinge. There is certainly no lack of beautiful and practical papers for covering the box and the exterior slipcase. What's most important, however, is to use bookcloth for the hinge. Bookcloth is just what it sounds like -- cloth that is backed with paper for use in bookbinding (and box making!). The cloth can be a simple cotton cloth or an elaborate silk or brocade. The patterns and colors available are extensive.

|

| A nice selection of bookcloth |

|

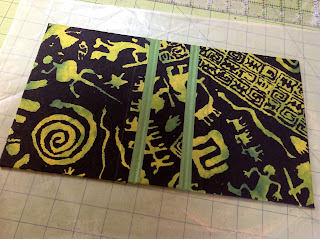

| Paper and bookcloth chosen for hinged box |

Because bookcloth is pliable, it is perfect for making a hinge. It is applied to the two large pieces of book board that form the base below the box and the lid on top of the box and to the book board that forms the spine, similar to the spine in a book. The chosen paper is cut to fit around the book board pieces and applied to the outside of the spine, although this is purely decorative. This is the view from the outside:

|

| Forming the hinge with bookcloth and covering the outside pieces with decorative paper, outside view |

And from the inside:

|

| Forming the hinge with bookcloth and covering the outside pieces with decorative paper, inside view |

Now it's time to cover the base box. This can be done in a variety of ways. It really depends on what you are comfortable with and what the paper is like. For a softer paper like what I'm working with here, it's easiest to cut one long piece that can wrap all the way around the outside of the box.

|

| Covering the base box with one continuous piece of decorative paper |

Note that there is a about 1/4 inch of paper overhanging the edge of the box. That edge will be trimmed at the corners and then glued flat against the bottom of the box. From the top side of the box, the corners are cut and the paper is glued flat against the inside edges of the box, overlapping onto the bottom of the box. It's a little tricky and I will go into it in more detail in a future post.

Next up is to cut the paper for the inside bottom of the box and the underside of the lid. I have chosen a nice bright yellow paper to bring out the yellow of the outside decorative paper. I believe this paper comes from Japan. (Must take better notes next time I go paper buying!)

|

| Paper used for inside lining |

Once these papers are affixed in place, it's time to attach the base box to the slip case. A generous portion of PVA glue, heavy weights, and several days' drying time later, we have a completed box:

|

| Completed hinged lid box |